Bruin Formula Racing

UCLA Formula SAE, 2014-2018

Bruin Formula Racing was perhaps the largest project I’ve worked on to date. Over four years with the team, I worked on a huge variety of projects, in many different roles. From my first year leading a small team to develop a small subsystem, to my final year as technical director, I found many opportunities for both personal growth, as well as for important contributions to the team. While primarily we are an engineering focused organization, the lessons I learned stretched far from those of technical nature. I learned about project organization, effective communication, how to operate with limited resources, how to consider tradeoffs, as well as how to lead teams of various scales. The following video, a video following our 2017 Season, serves as a good introduction to our team and our vehicle: After my four years of the team, I penned a personal reflection on my time there and my main takeaways. Additionally, I describe in depth about the various roles I took on. You can view my words here. This reflection forms the basis for the material on this website, as such there is significant overlap.

To view a sample case for a project design process, please check out the Pneumatic Shifting page.

Background

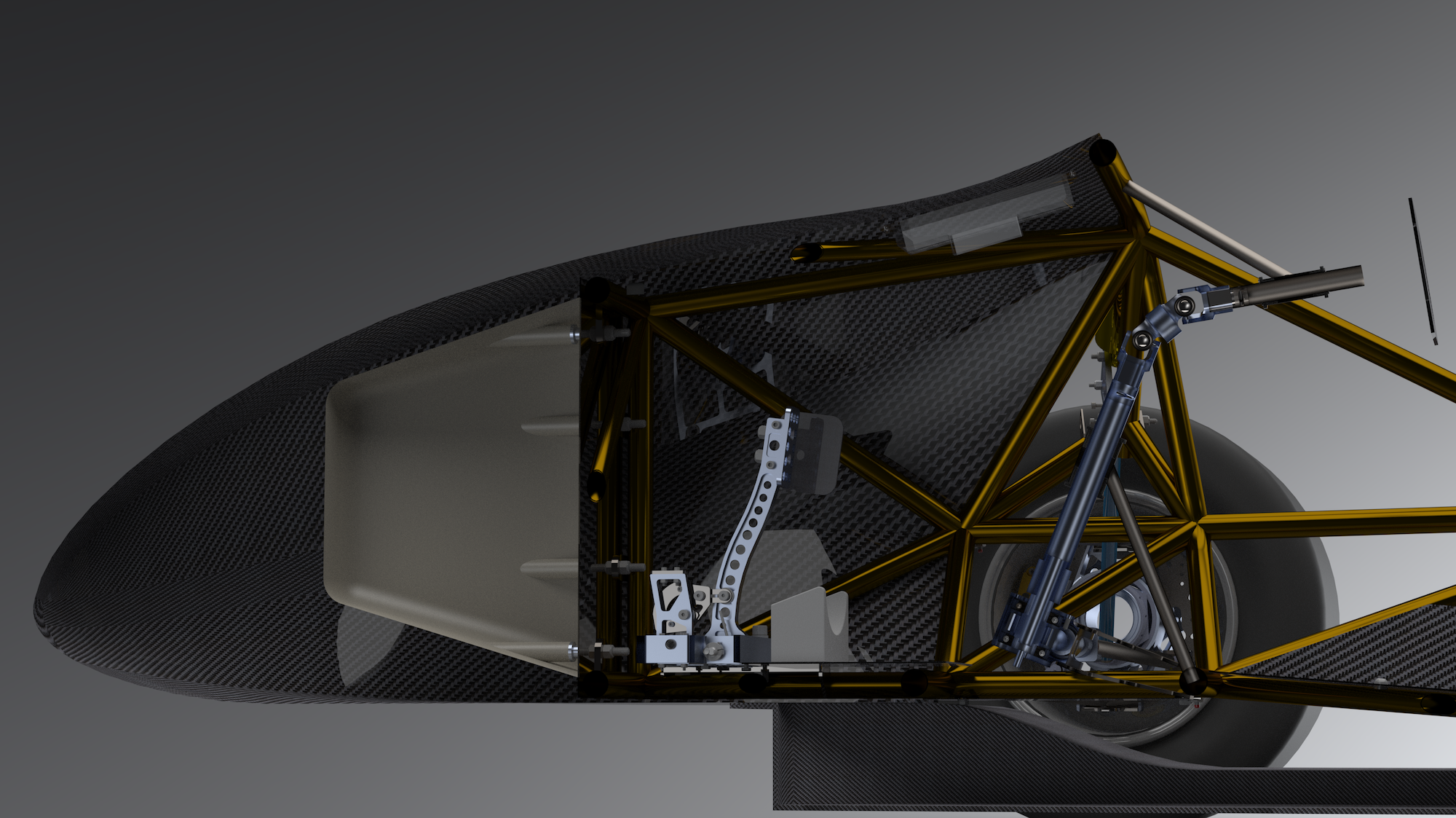

Formula SAE is a collegiate program operated by the Society of Automotive Engineers (SAE). Over the course of a year, students will design, build and race a small formula-style vehicle. These vehicles are generally powered by motorcyle engines, and can easily outpace most road-legal vehicles from 0-60. These vehicles are then entered into competition, which generally takes place in the spring. UCLA’s Formula SAE team (known as Bruin Formula Racing) was founded around 2012, and the first completed vehicle competed in the 2014 Formula SAE West competition. I joined the team in fall 2014, and left the team in June 2018. Over that period, we progressed rapidly as a team, developing into a full fledged team. My first year on the team, we didn’t finish our vehicle in time for competition. By my last year, we were a competitive team with established processes and organizational structure. At some schools, Formula SAE is an established program, well integrated with the school’s curriculum, facilities and faculty. As our program is fairly young, we often didn’t have these advantages, and thus a large component of our efforts went to resource management and cost optimization.

My roles

Over my four years on the team, I took on a variety of roles on the team. Fall of my Freshman year (2014), I decided to join Formula SAE, as I had previously done FIRST Robotics on the Gunn Robotics Team in high school, and loved the hands-on aspect of engineering. My first year on the team, I joined the controls team, which focused on driver interface (such as brakes, seat, and pedal box). Due to some experience I had with pneumatics from my time on the robotics team, the I took an interest a pneumatics shifting project. The goal was to add in a shift-by-wire system to our vehicle so the driver could utilize electronic controls to shift, instead of using a shifter stick. Given my previous experience with pneumatics on robotics, as well as my continued contributions, I soon became de facto in charge of that project, as our overall lead was busy with other controls projects. This began a two year stint as the pneumatic shifting lead for MKII. Along with another co-lead, we more or less started from nothing but the idea, and eventually built the entire system. You can find more information here: Pneumatic Shifting.

Over my four years on the team, I took on a variety of roles on the team. Fall of my Freshman year (2014), I decided to join Formula SAE, as I had previously done FIRST Robotics on the Gunn Robotics Team in high school, and loved the hands-on aspect of engineering. My first year on the team, I joined the controls team, which focused on driver interface (such as brakes, seat, and pedal box). Due to some experience I had with pneumatics from my time on the robotics team, the I took an interest a pneumatics shifting project. The goal was to add in a shift-by-wire system to our vehicle so the driver could utilize electronic controls to shift, instead of using a shifter stick. Given my previous experience with pneumatics on robotics, as well as my continued contributions, I soon became de facto in charge of that project, as our overall lead was busy with other controls projects. This began a two year stint as the pneumatic shifting lead for MKII. Along with another co-lead, we more or less started from nothing but the idea, and eventually built the entire system. You can find more information here: Pneumatic Shifting.

After two years, in which pneumatic shifting was installed on MKII for competition in June 2016, I transitioned to a new role. The team made the decision to remove pneumatic shifting, as the system was overall unreliable and a bit premature for our young team. Instead, I took on the responsibility as the data acquisition lead for MKIII, aiming to outfit the car with sensors which would allow us to gather valuable design validation. Again, I was building a new team from the ground up– most of my members were new. In our design phase, I worked with the various mechanical leads to integrate the sensors mechanically into their designs while also making considerations for the electronics which would power our data acquisition. By mid-year, our team also picked up another responsibility – we needed to work on the engine EFI(Electronic Fuel Injection), as we had not made much progress with that. A couple of months later, I was also put in charge of the mechanical side of powertrain development as well, as the team was falling behind as well as in need of better organization. This period was my most stressful on the team, as I was often spending 50-60 hours working on Formula SAE in addition to my normal student responsbilities. You can find more information on DAQ Electronics and Powertrain here Data Acquisition and Powertrain.

Following this intense period, I became the leading candidate to be the next technical director, the lead engineer on the team in charge of all technical decisions. I officially took this position in June 2017. In the oncoming year, I worked with sponsors, plunged headfirst into learning about other subsystems, worked on media and branding, worked to handle crises with individual subsystems, made difficult technical decisions, and took on overall team project management. By the end, we had the most successful car ever built in the young UCLA Formula SAE’s history. You can find more information here: Technical Director.

Takeaways and Personal Development

Over my four years, I developed countless skills and techniques, both technical and non-technical. One aspect I developed were a series of guiding principles and philosophies for engineering project leadership. I was a lead for all four years on my team, and picked up a good deal of leadership experience, both for people and for projects. Some of my biggest takeaways from Formula were these “soft” engineering skills which are often not taught in school. As our team relies on voluntary participation, I had to learn how to strike a balance between pushing team members to complete work while also keeping people happy and engaged. In terms of communication, I had to learn to effectively assign tasks to team members, convey design decisions to team members, as well as give presentations both in technical design reviews and general presenetations to sponsors. I had to balance short-term and long-term goals, as well as consider the resources needed to fulfill our goals. I honed my project organization skills, as I had to learn to set timelines which accounted for setbacks, create clear documentation, manage tradeoffs between money, time, and quality, and manage both people and resources such as manufacturing resources and manpower on different projects.

In addition to the major experience in leadership and management, I also gained an appreciation for part design. From creating CAD models which are easily modified with proper planes and dimension, to conducting FEA on load bearing parts, to creating drawing sheets with tolerances with an eye towards manufacturing, to creating DXFs of parts to be waterjet, I gained familiarity with all aspects of the part design process. Design for manufacture was a critical part of our team, as we had to work within both our own manufacturing capabilities and also with an understanding of the tradeoffs between complexity and manufacturability. Thanks to Formula, I am now comfortable working with large assemblies in Solidworks, and no longer fear the millions of rebuild errors which occur when I change a mate configuration. I also learned Solidworks Visualize to produce renders of our vehicle for public relations and sponsorship opportunities.

Conclusion

In the end was it worth it? That’s a question I always wonder. I know I gave up 4 years of friendships I could have grown, every single Saturday for a good part of two years, and perhaps a bit of my GPA as well. But looking back, I am always amazed that I built this car (with help of course!), and am thankful for the friendships I forged. They say the best friendships are forged with mutual suffering, and we certainly had the mutual suffering part down. Not many people can say they built race cars in their free time, and I’m really proud to point to this car and know that I created something awe-inspiring. A real car that not only drives but drives fast, and keeps my head pushed against the headrest when I push the throttle. While certainly there were many lows, perhaps more than any should come from a voluntary club where nobody is even paid, these really served to amplify the highs, the moments of pure joy at seeing your hard work pay off. Hearing the engine roar to life, an immense sense of pride comes from within, knowing that I helped build this magnificent beast. Overall, Formula taught me priceless life skills, and I had a blast along the way.